Orbital Equipment

Published on: 15th October 2025

Overview

Orbital Equipment Ltd, a leading plant hire and civil engineering company in the South East, has expanded its transport fleet with the addition of a Sterling Miniload beavertail body, mounted on a DAF XB 4×2 12T chassis.

With over 700 machines available for hire and two decades of industry experience, Orbital is known for delivering an extensive range of plant equipment, from everything tracked and wheeled, backed by reliable service. Their investment in the Miniload reflects a commitment to urban-ready, agile transport solutions capable of navigating today’s increasingly restricted and complex job sites.

Why the Sterling Miniload?

Agility, uptime, and reliability are critical to Orbital’s operations. The Sterling Miniload combines compact design with robust build quality, offering the ideal solution for short-haul, urban logistics, and tight-access delivery of compact plant such as mini diggers, dumpers, and scissor lifts.

This body is purpose-built for plant hire companies needing fast turnaround times, dependable performance, and a vehicle that can comfortably handle the demands of daily site logistics – especially within housing developments, city centres, and civil engineering zones.

The Sterling Miniload – Mounted on a DAF XB 4×2 Chassis

The pairing of the Sterling Miniload with the DAF XB 4×2 12T chassis offers a powerful yet agile beavertail that’s perfectly suited for dense urban environments and restricted sites.

Compact but Capable

Built for 7.2–14T chassis, the Miniload retains full plant body functionality within a smaller footprint. The double-break beavertail, low deck height, and efficient loading ramps allow for the safe and easy transport of small-to-mid-sized equipment – ideal for inner-city deliveries.

Why the DAF XB?

The DAF XB chassis enhances the Miniload’s performance with:

- Tight turning radius for urban manoeuvrability

- Euro 6 emissions compliance for environmental standards

- Lightweight design for maximum payload

- Driver-focused features for comfort during frequent stops

Together, this creates a nimble yet tough beavertail truck that excels in urban logistics, while lowering total cost of ownership through fuel efficiency and reduced wear.

Optimised for Urban Logistics

- Maneuvers easily through housing estates, narrow roads, and busy sites

- Quick, safe load/unload cycles for improved productivity

- Perfect for groundworks, utilities, access hire, and local authority projects

- A reliable choice for frequent, short-range plant movements

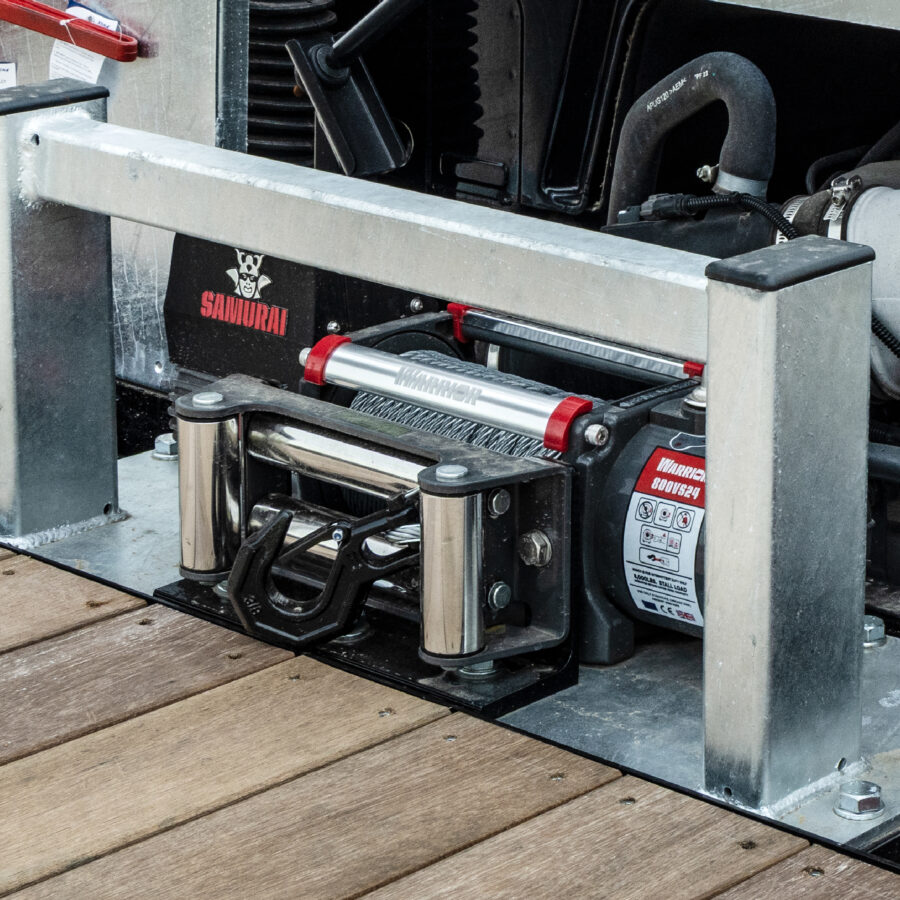

Sterling Engineering Quality

- Galvanised steel components and two-pack paint finish for durability

- Enclosed wiring and sealed electrics for low-maintenance operation

- Stainless steel toolboxes, lashing rings, and fall arrest equipment fitted as standard

Operational Benefits for Orbital Equipment Ltd

The Miniload has been selected to meet Orbital’s needs for efficiency, fleet adaptability, and safety in real-world conditions. Key operational advantages include:

-

Built for Restricted Sites

- Compact size and tight turning capabilities are ideal for jobs in high-density urban areas

- Accesses dense inner city streets, narrow lanes, and congested environments where larger trucks struggle to navigate or simply can’t go

-

Flexible Fleet Utility

- Fills the gap between flatbed vans and full-size beavertails

- Handles a wide range of machines: micro diggers, trench rollers, small dumpers, and more

-

Low Maintenance, High Uptime

- Simplified body design, enclosed electrics, and corrosion-resistant fittings reduce service intervals and unscheduled downtime

- Keeps vehicles on the road and delivering, not in the workshop

The Result: A Smarter Way to Move Small Plant

By adding the Sterling Miniload to its fleet, Orbital Equipment Ltd has strengthened its ability to deliver fast, efficient, and reliable plant transport across the South East. The combination of urban-friendly dimensions, rugged build, and industry-leading safety features ensures the vehicle fits seamlessly into Orbital’s operations – supporting their promise to customers: equipment delivered on time, every time.

The Miniload paired with the DAF XB is more than a compact plant body – it’s a strategic investment in fleet agility, operational uptime, and enhanced service delivery in a demanding market.