Complying with work at height regulations on trucks

Published on: 24th July 2023

HOW DOES THE LAW DEFINE WORKING AT HEIGHT?

Working at height is work in any place where, if precautions are not taken, a person could fall a distance liable to cause personal injury. So, HSE considers you as working at height if you: – work above ground/floor level, could fall from an edge, through an opening or fragile surface or, – could fall from ground level into an opening in a floor or a hole in the ground. Whilst this may seem extreme and you may well say, “I could call anything a work at height fall!” neither a slip or a trip on the level or a fall that occurs whilst ascending/descending a permanent staircase in a building are considered a work at height incident.

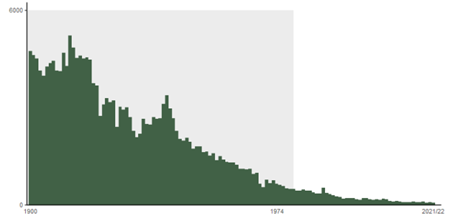

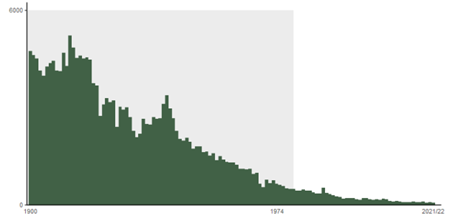

Figure 1 – Number of fatal injuries to employees in Great Britain, 1900-2021/22. Source: RIDDOR and earlier reporting legislation.

We may complain about the extremes that health and safety has gone to, and indeed may think it has gone too far but it’s important to consider the origin or cause an issue that prompts regulation. Historic structures such as medieval cathedrals or pyramids clearly show that working at height has been necessary centuries. Fall from height fatalities were high on such projects due to little to no work at height safety methods. Throughout the industrial revolution and even when skyscrapers were built in our cities, laws for working at height were not introduced until 1974 (See Figure 1). The laws were designed to regulate health and safety and ultimately put more onus and responsibility on employers to provide for the welfare of their employees.

As a direct result of the 1974 legislation, fatal injuries to employees fell by 86% in the following 40 years. Safety equipment design continues to improve and safe working practices are becoming more prevalent but there is still more to be done to minimise (and ultimately eliminate) the risk of working at height.

WHAT ARE YOUR REQUIRMENTS AS AN EMPLOYER?

Each and every regulation. Especially those where there is risk of a fall liable to cause personal injury.

Placing the duty on employers and those who control any work at height activity (such as facilities managers or building owners who may contract others to work at height), you must ensure:

- All work at height is properly planned and organised.

- Those involved in work at height are competent to do so.

- The risks from work at height are assessed, and appropriate work equipment and/or fall prevention is selected and used.

- The risks of working on or near fragile surfaces are properly managed.

- Any equipment used for work at height is properly inspected and maintained.

However, not all the responsibility lies with the employer. It is just as important that employees recognise that they have a legal duty to take reasonable care of themselves and others who may well be affected by their actions. They must cooperate with their employer and adhere to health and safety protocol and practices provided. The consequences of not taking work at height seriously is clear. Potential serious injury or death should be enough to ensure all precautions are taken. However, substantial fines are still being dealt to companies who come in breach of the regulations. In one case in 2016, directors of a company that was not managing work at height risks appropriately were sentenced to time in prison.

HOW DO I PREVENT FALLS WHEN USING TRUCKS?

Here are some examples.

Whilst edge protection/fall arrest is not yet stipulated by the law, many companies wisely choose to specify it on their trucks. Fall restraint systems running along the sides of the body come in different variations, the most common of which are Post & Socket or Fold-out.

The simplest system, post & socket is exactly as described. Whilst it limits working space to within the deck width, it is simply removed and stowed when loading over-width machines. Fold-out systems usually come with a walkway supplied which provides additional width and enables operators to walk beside wide machines on the truck. However, the system is more complex to remove when transporting over-width machines. Regardless of which system is most appropriate for your operation, they must be coupled with safe access, usually by an access ladder situated on the side of the vehicle. Locating the ladder near the headboard means a grab handle can be fitted to the headboard providing the necessary three points of contact.

Sufficient lighting is crucial to aiding safe loading and minimising fall from height risk for your operator, particularly when working at night and/or in low light areas such as tunnels. LED work lights mounted high on the headboard or back of the cab provide the necessary illumination.

Providing the correct decking material can also minimise work at height risk. Mesh decking and non-slip surface options provide improved grip, particularly in wet conditions which can prevent falls caused by slipping.